Spreading of complex fluids with a soft blade, Marion Krapez, Anaïs Gauthier, Jean-Baptiste Boitte, Odile Aubrun, Jean-François Joanny and Annie Colin, Physical Review Fluids, 7, 084002 (2022)

https://journals.aps.org/prfluids/abstract/10.1103/PhysRevFluids.7.084002

Résumé :

The spreading of complex fluids is not only a part of our everyday life but also a

central process in industry to produce functional thin films or protective coatings. Here

we consider the spreading of polymer solutions with an elastic blade that deforms during

the coating (similarly to a brush or a finger). By using complex fluids with well-chosen

rheological properties, we disentangle the effects of shear viscosity, shear thinning, and

normal stresses. We reveal two counterintuitive results : First, the mechanical work needed

to spread a given volume of a shear-thinning fluid is higher than for the same volume of an

equivalent Newtonian fluid at constant spreading velocity. Second, the first normal stress

difference, which usually leads to remarkable behaviors such as the swelling of jets or the

rise of the fluid on a rotating rod, has strikingly negligible effect here.

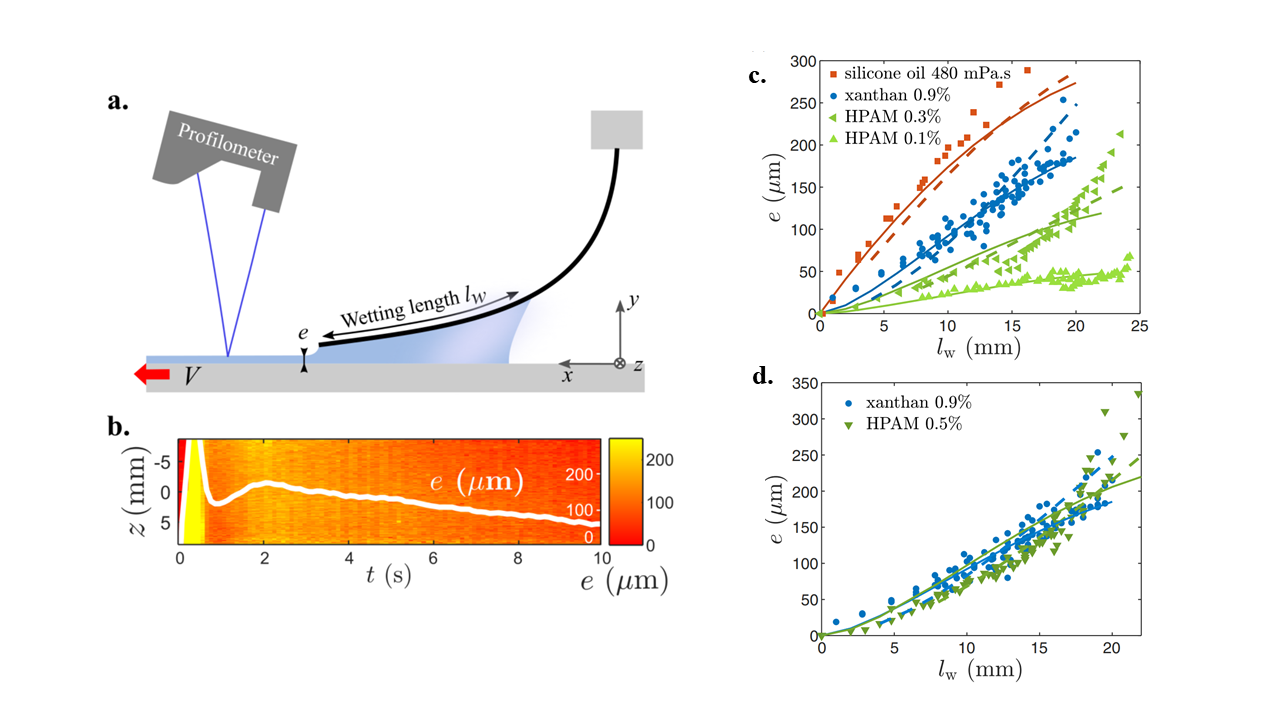

(a) Schematic representation of the soft blade coating experiment. (b) Map of the central part of

the film for xanthane 0.9% during the spreading, as a function of the width z and time t. The color code varies

from e = 0 (red) up to e = 250 μm (yellow). The first peak is an artifact and is not taken into consideration.

The white line shows the mean thickness e(t) over the film width as a function of time. (c) Evolution of the fluid thickness e with the wetting length lw for two shear-thinning fluids (xanthan 0.9% in blue, HPAM 0.3% in green, and HPAM 0.1% in light green) and a Newtonian fluid (silicone oil, η=480 mPa s in red). The markers correspond to the experimental data measured for different initial fluid volumes.

The continuous lines show the scaling law with prefactors 0.17 (for silicone oil) and 0.06 (for xanthan

and HPAM) corresponding to the best fits. The dashed lines are the numerical solutions. (d) Comparison of

xanthan 0.9% and HPAM 0.5% (dark green). Xanthan is purely shear-thinning while HPAM also generates normal forces at high shear rate. The blue symbols correspond to the same experiments in (c) and (d).

(a) Schematic representation of the soft blade coating experiment. (b) Map of the central part of

the film for xanthane 0.9% during the spreading, as a function of the width z and time t. The color code varies

from e = 0 (red) up to e = 250 μm (yellow). The first peak is an artifact and is not taken into consideration.

The white line shows the mean thickness e(t) over the film width as a function of time. (c) Evolution of the fluid thickness e with the wetting length lw for two shear-thinning fluids (xanthan 0.9% in blue, HPAM 0.3% in green, and HPAM 0.1% in light green) and a Newtonian fluid (silicone oil, η=480 mPa s in red). The markers correspond to the experimental data measured for different initial fluid volumes.

The continuous lines show the scaling law with prefactors 0.17 (for silicone oil) and 0.06 (for xanthan

and HPAM) corresponding to the best fits. The dashed lines are the numerical solutions. (d) Comparison of

xanthan 0.9% and HPAM 0.5% (dark green). Xanthan is purely shear-thinning while HPAM also generates normal forces at high shear rate. The blue symbols correspond to the same experiments in (c) and (d).